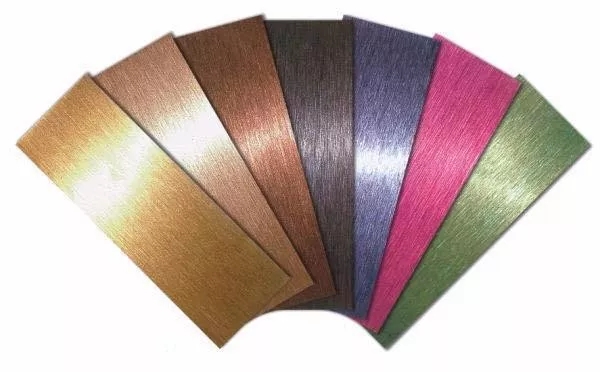

Stainless steel wire drawing board

Stainless steel wire drawing board generally refers to surface texture plus collectively, the former name is frosted board, the surface of the grain mainly has straight lines, chaotic lines (and lines).

1. Stainless steel brushed ruled board: It is usually processed by mechanical friction on the surface of stainless steel to obtain a line with a straight surface condition. The stainless steel surface is like a silky texture, which is just a process of stainless steel. The surface is matt, look carefully at the top of the texture, but can not touch it. It is more wear-resistant than the general bright stainless steel, it looks more graded and has a good decorative effect.

2, stainless steel brushed chaos (and grain) board: surface sand pattern from a distance is composed of a circle of sand pattern, the near is no specification of chaos, is the grinding head up and down irregular swing grinding, Then electroplating is colored. The surface of this grain is matte and the requirements for fabrication are also high.

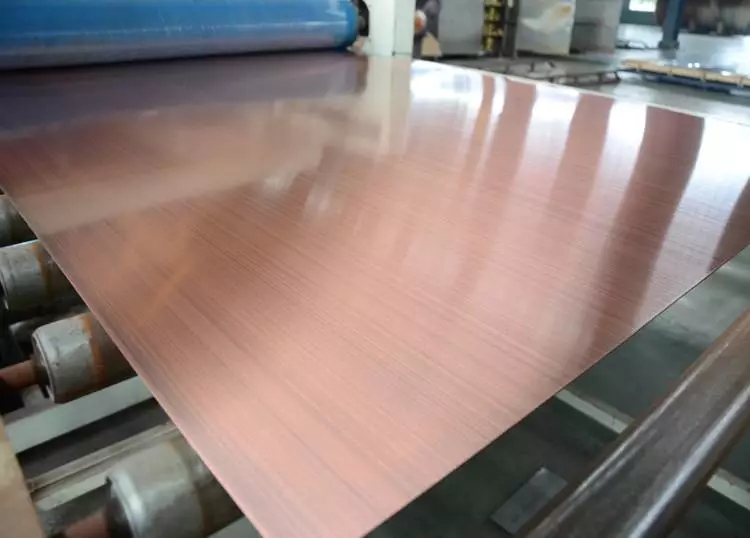

Stainless steel oil mill wire drawing board

Stainless steel oil brush drawing board is a kind of brushed stainless steel. The main appearance is different from oil brush drawing. Because the belt is sanded with oil or water and oil, the matte surface is more delicate and uniform, and the anti-rust effect is better.

Stainless steel mirror panel

Stainless steel mirror panel: 8K plate, also known as mirror panel, is polished on the stainless steel plate by polishing equipment with polishing liquid, so that the surface brightness is as clear as a mirror.

Stainless steel mirror panel use: mainly used in building decoration, elevator decoration, industrial decoration, facility decoration and other stainless steel products.

Stainless steel mirror panel features: stainless steel plate surface is smooth, with high plasticity, toughness and mechanical strength, corrosion resistance to acid, alkaline gases, solutions and other media.

Stainless steel mirror panel principle: The process of stainless steel mirror panel processing can be divided into two methods: general grinding and fine grinding. Generally speaking, the stainless steel plate is processed on the polishing machine, and the slower the traveling speed, the more the number of grinding groups More, and this effect will be very good.

When the stainless steel plate is processed by polishing equipment, the first step is to sand the plate, and then the stainless steel plate is placed in the polishing liquid. The grinding process is carried out by 8 sets of different grinding heads. The grinding process is basically the treatment of the surface of the stainless steel plate. This step is mainly to remove the oxide layer on the surface of the stainless steel plate. After the above process, it can be washed and dried. Stainless steel titanium plate

The stainless steel titanium plate is polished with a stainless steel plate to form an 8K mirror surface. A large vacuum coating device is used to coat a layer of high wear-resisting and corrosion-resistant gold-titanium titanium nitride. Titanium plate is used for advertising materials because of its luster, such as titanium medals, titanium characters and so on. As an advertising or decorative material, titanium and stainless steel plates can be used for rotten machining as well as stainless steel titanium gold wire drawing plates.

Stainless steel rose gold plate

Rose gold plate is also called rose gold stainless steel plate, or color stainless steel rose gold plate. The manufacturing process is not simply to apply a layer of colorant to the surface of the stainless steel, but through a very complicated process. The colored surface has the advantages of colorful color, bright color, bright color, softness, elegance and smoothness.

The anti-fingerprint stainless steel plate is coated with a transparent colorless nano-scale coating on the surface of the stainless steel by roller coating or spraying to improve the anti-fouling performance of the stainless steel surface, so that the surface dust, fingerprints and other stains of the stainless steel are easily used during use. clean.

Product application: non-fingerprint stainless steel plate can be used in elevators, security doors, car interiors, hotel decoration, home appliances, aerospace equipment, medical equipment, lighting, furniture and so on.

Stainless steel tread plate

The stainless steel tread plate is a pattern in which the surface of the steel plate is uneven, and is used for a place where smoothness and ornamental are required. The embossing or embossing is carried out by a patterned work roll, the work rolls of which are usually processed with an erosive liquid, and the depth of the irregularities on the plate varies from pattern to pattern, about 20-30 microns. Common shapes: herringbone, T-shaped, willow-shaped and lentils.

Main advantages: durable, durable, wear-resistant, decorative effect. Visually beautiful, high quality, easy to clean, maintenance-free, anti-shock, anti-pressure, anti-scratch.

Product application: Tread plate is more commonly used in chemical, railway vehicles, platforms and other places where strength is required.

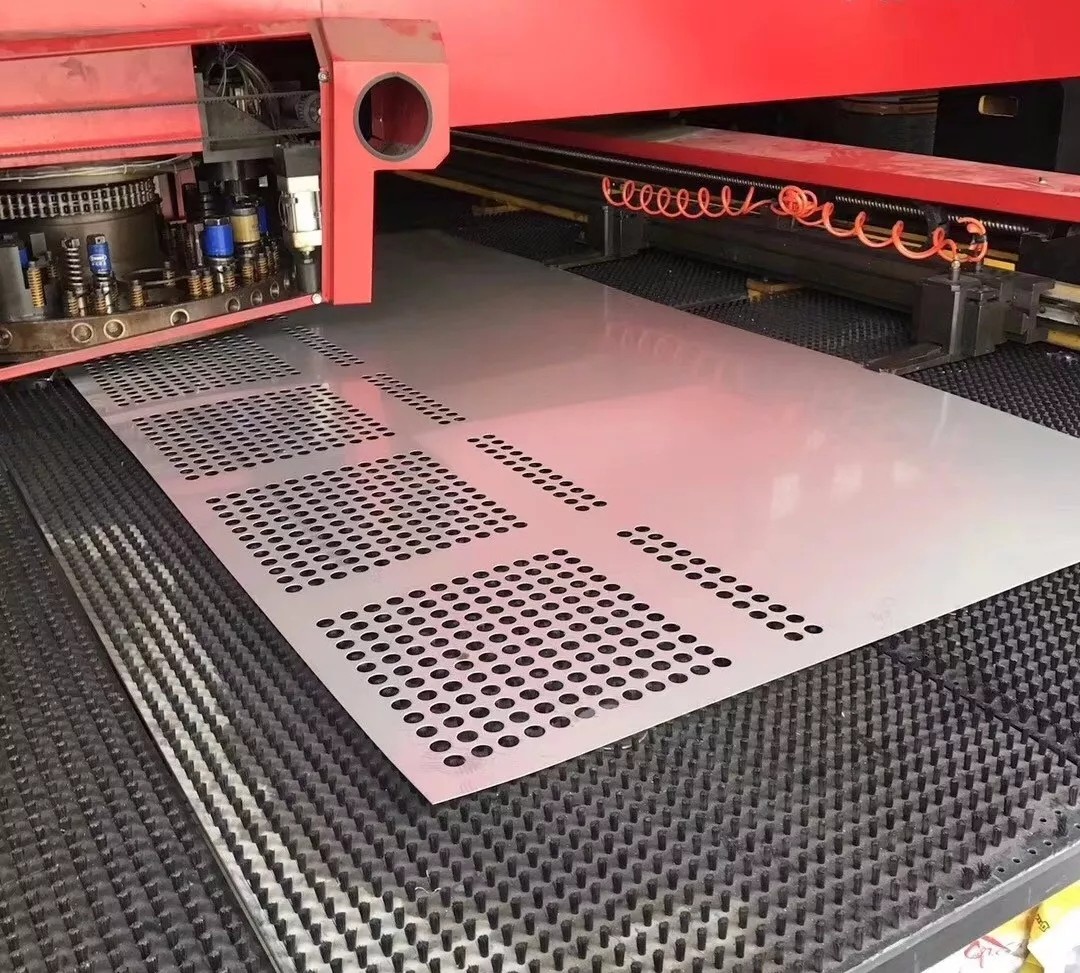

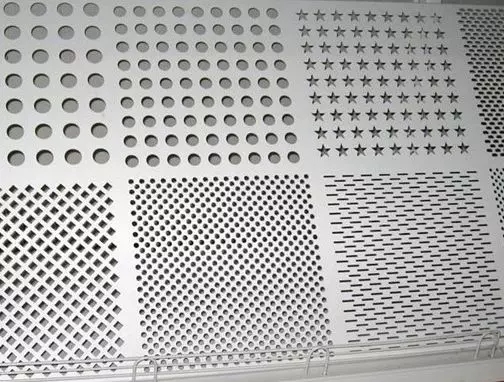

Stainless steel punching plate

Stainless steel perforated plate refers to a perforated stencil made of stainless steel. There are many advantages to using perforated plates made of stainless steel. The main advantages are: smooth, smooth, beautiful, durable and wide-ranging.

Stainless steel perforated plate classification generally: 1, round hole stainless steel punching plate; 2, square hole stainless steel punching plate; 3, shaped stainless steel punching plate; 4, microporous stainless steel punching plate; 5, non-slip stainless steel punching plate ; 6, road attraction, sound-proof stainless steel perforated plate.